3 min read –

Make Mining Clean At Last –

Stop The Leakage of Toxic Waste –

Use Advanced Filter Press Technology –

Indonesia’s mining industry is a cornerstone of the national economy, powering growth through exports of key commodities like nickel, coal, copper, gold, and tin.

As the world’s leading nickel producer (accounting for over 60% of global supply) the sector has expanded rapidly, especially in Sulawesi and Maluku, driven by demand for electric vehicle batteries and renewable energy technologies.

In 2024, mineral extraction exceeded 1.6 billion tons, according to the Ministry of Energy and Mineral Resources (ESDM).

However, this progress generates massive waste: mining tailings.

Tailings are the fine-grained residues left after valuable minerals are extracted from ore.

They consist of crushed rock particles, water, trace heavy metals (such as arsenic or mercury), and processing chemicals (like sulfuric acid or cyanide in hydrometallurgy), forming a slurry.

These wastes pose severe risks: leaching toxins into soil and waterways, causing acid mine drainage, biodiversity loss, groundwater contamination, and health issues like heavy metal poisoning in nearby communities.

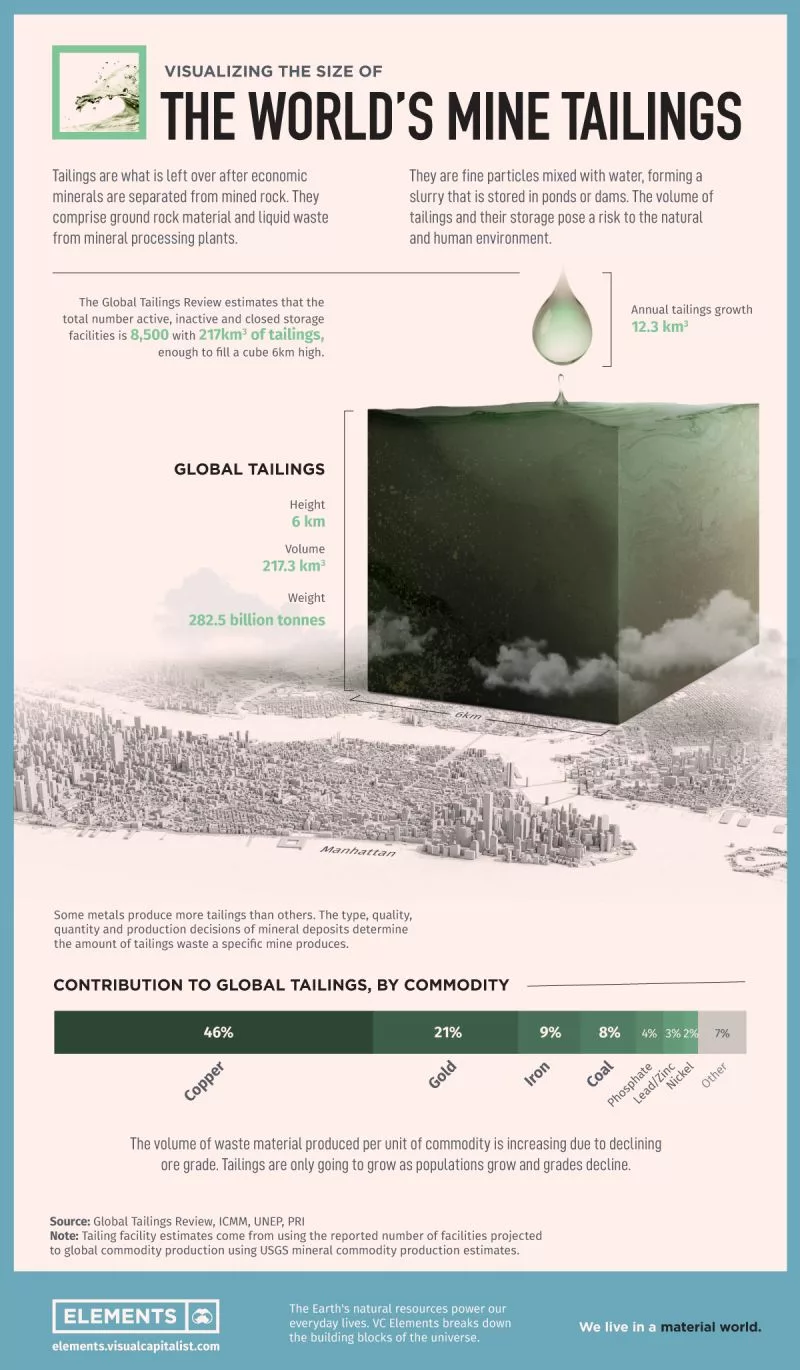

The attached infographic dramatically illustrates the global scale of this challenge.

According to the Global Tailings Review, there are about 8,500 tailings storage facilities worldwide, holding roughly 217 km³ of tailings, enough to form a cube 6 km high, visually dwarfing Manhattan.

Global annual growth adds around 12.3 km³, with contributions dominated by copper (46%), gold (21%), iron (9%), and others including nickel (around 3%).

Besides, declining ore grades are increasing tailings per unit of metal produced.

Current tailings management worldwide and in Indonesia often relies on storing slurry in large impoundments or ponds behind earthen dams.

This allows partial water recycling but leaves high moisture, heightening vulnerability to heavy rainfall, earthquakes (prevalent in Indonesia), or poor design.

In Indonesia, many nickel HPAL facilities at hubs like the Indonesia Morowali Industrial Park (IMIP) use such dams.

Other operations like PT Freeport discharge into rivers, a method criticized for pollution, but used because the site is too risky to build a dam (rainfall, topography, earthquake).

Smaller sites frequently use unlined ponds, worsening leakage across vast areas.

These practices have proven dangerously inadequate, as recent disasters show.

In March 2025, multiple tailings incidents struck IMIP in Central Sulawesi.

Heavy rains caused a breach, releasing liquefied toxic tailings into the Bahadopi River, flooding the Labota village and exposing over 1,000 people to heavy metals.

On a different site, a collapse buried workers, killing three excavator operators.

These failures, linked to poor pond construction, intense tropical rainfall, and rapid expansion, highlight systemic issues in oversight and safety prioritization.

One of the deadliest mining disasters in history is the collapse of the Brumadinho (tailings) dam in 2019 in Brazil, at the VALE iron ore facility.

Fortunately, proven technology provides a safer, more efficient path: the filter press machine, especially suited to hydrometallurgy for metals like nickel, copper, and gold.

The process pumps tailings slurry into chambers between filter plates under high pressure (up to 30 bars).

Filter cloths separate solids from liquids: clean filtrate water is recovered for reuse, while solids form compact, stackable dry cakes with moisture reduced to 15-20%.

This achieves up to 80% volume reduction, recovers about 90% of water (essential in water-intensive mining), stabilizes waste to curb leaching, and eliminates large dam risks, ideal for Indonesia’s seismic, high-rainfall zones.

A trusted leader is Choquenet, a French company with over 100 years of expertise since 1925. With approximately 4,500 filter presses installed in more than 90 countries, Choquenet offers proven credibility in mining tailings filtration.

Their robust, customizable machines (up to 2500x2500mm) feature ATEX compliance for hazardous environments, innovative cake scraping, high reliability, and low maintenance.

Shifting from risky pond storage to advanced filter press technology can greatly reduce tailings impacts in Indonesia’s mining sector.

We are Cintasia, Sales Representative of Choquenet in Indonesia.

Contact us today to schedule a free consultation.

And discover how Choquenet can tailor a filtration solution for your tailings and concentrates dewatering challenges.

PS: If you enjoyed this article, check out our blog for more. We have published 165+ other articles. Go to www.cintasia.com/news-insights

Picture: Visual Capitalist